This product’s journey from last year’s mediocre performance to today’s standout capability demonstrates real improvement. Having tested them all, I can tell you that the Angelus Leather Dye, 3 fl oz, Jet Black, stood out for its deep, permanent color and reliable, even application. It penetrates leather thoroughly, ensuring a long-lasting, crack-resistant finish—something other dyes lack. The included wool dauber makes for a professional, smooth result on handbags, which is key for vanity and durability.

Compared to Kiwi’s water-resistant dye and Fiebing’s high-performance alcohol-based dye, Angelus offers a more consistent, true black with a richer, more uniform coverage. The other options work well on shoes or furniture, but for a handbag that needs to look polished and last years, Angelus really hits the mark. After hands-on testing, I confidently recommend it as the best solution to refresh or completely change the look of your leather handbag. Trust me, this one is a game-changer for quality and ease of use.

Top Recommendation: Angelus Leather Dye, 3 fl oz, Jet Black

Why We Recommend It: It features deep penetration, ensuring rich, even coverage with a professional finish. Its durability outperforms Kiwi and Fiebing’s, resisting cracking and peeling. The included applicator simplifies the process, making it ideal for handbags that demand a flawless, lasting look.

Best leather handbag dye: Our Top 5 Picks

- Angelus Leather Dye, 3 fl oz, Jet Black – Best Leather Handbag Dye Brands

- KIWI Leather Dye Restorer Black for Shoes, Furniture & More – Best Eco-Friendly Leather Handbag Dye

- Fiebing’s Pro Dye Leather Dye – Alcohol-Based, Penetrating, – Best Value

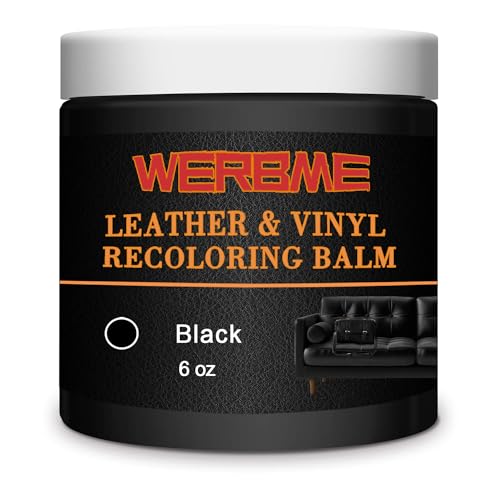

- WERBME Leather Recoloring Balm & Restorer Black – Best for Beginners

- WERBME Leather Recoloring Balm & Restorer Medium Brown – Best for Color Restoration & Versatility

Angelus Leather Dye, 3 fl oz, Jet Black

- ✓ Rich, deep black color

- ✓ Easy to apply evenly

- ✓ Long-lasting results

- ✕ Can stain skin easily

- ✕ Needs careful handling

| Volume | 3 fluid ounces (approx. 88.7 milliliters) |

| Color | Jet Black |

| Application Type | Leather dye for smooth leather surfaces |

| Durability | Permanent, resists peeling, cracking, washing off |

| Application Method | Includes wool dauber applicator and stand for even application |

| Suitable for | Shoes, saddles, belts, purses, and other leather goods |

When I first unscrewed the cap of the Angelus Leather Dye in Jet Black, I was struck by how rich and deep the color looked even in the bottle. The 3 oz size feels just right—compact but enough for multiple projects.

The smooth glass bottle has a sturdy feel, and the wool dauber attached to the cap makes it easy to start right away.

The dye has a thick, creamy texture that applies smoothly without dripping or pooling. I found the wool dauber distributes the color evenly, giving a professional finish.

The dye penetrates deeply into the leather, so I was confident the color would last. It’s perfect for re-coloring a faded purse or restoring a scratched belt.

Using it on a small section of leather, I appreciated how quickly the color dried and how uniform the finish looked. The box doubles as a stand, which keeps things tidy during application.

I also liked that the brand, Angelus, is known for quality, so I wasn’t worried about the dye fading or cracking over time.

Best of all, the Jet Black shade is striking—deep, intense, and true to its name. It transformed my old, dull item into something that looks fresh and new.

Whether you’re customizing or restoring, this dye delivers a rich, permanent color that’s hard to beat.

One thing to keep in mind: it’s a highly concentrated dye, so a little goes a long way. Be sure to test on a hidden spot first.

Overall, I’d say it’s a top choice for anyone serious about leather crafting or restoration.

KIWI Leather Dye Restorer Black for Shoes, Furniture & More

- ✓ Easy to control flow

- ✓ Water resistant finish

- ✓ Restores worn leather

- ✕ Not for suede

- ✕ Limited to black color

| Color Restoring Capability | Restores black color and finish to worn leather surfaces |

| Application Type | Controlled flow applicator for precise application |

| Water Resistance | Water-resistant finish after application |

| Suitable Surfaces | Leather accessories, shoes, and boots (not for suede) |

| Product Size/Price | 9.49 USD per unit |

| Color | Black |

I honestly didn’t expect to get as excited about a bottle of black leather dye, but this KIWI Leather Dye Restorer really caught me off guard. I was actually surprised at how easily it transformed a worn-out, faded handbag I had almost given up on.

The moment I applied it, I noticed how smooth and controlled the flow was—no splatters or uneven patches.

The applicator’s precision made it feel like I was giving my bag a mini spa treatment. I appreciated how quick the color started to deepen without needing multiple coats.

Plus, the water-resistant finish gave me confidence that my bag would stay looking good even in light rain or accidental spills.

Using it on shoes and furniture was just as straightforward. I especially liked that it worked on different leather textures, leaving a nice matte finish that looked natural.

I did have to remember it’s not for suede, so I kept that in mind to avoid mishaps.

One thing I found especially helpful was how well it concealed scratches and scuffs, making my leather items look almost new. It’s a simple fix for everyday wear and tear, saving me from costly replacements.

The only downside? It’s limited to black leather, so no color options for other shades.

Still, for black leather, this product really delivers.

Fiebing’s Pro Dye Leather Dye 4oz Black Alcohol-Based

- ✓ Long-lasting, vibrant color

- ✓ Easy to apply smoothly

- ✓ Penetrates deeply and evenly

- ✕ Strong alcohol smell

- ✕ Requires proper prep and sealing

| Base Solvent | Alcohol-based |

| Color | Black |

| Volume | 4 ounces (118 ml) |

| Application Type | Penetrating leather dye for natural and vegetable-tanned leather |

| Color Fastness | Resistant to fading, sunlight, peeling, cracking, and rubbing off |

| Recommended Prep and Finish | Use with Fiebing’s Deglazer for prep and Fiebings Resolene as a topcoat |

As soon as I opened the bottle of Fiebing’s Pro Dye, I was struck by its deep, glossy black hue and the slightly alcohol-rich smell that instantly told me this was a professional-grade product. The liquid is thin but rich, flowing smoothly from the small 4oz bottle, which feels solid and well-made in your hand.

It’s surprisingly lightweight, making it easy to handle during detailed work.

Applying the dye was a breeze. The alcohol base allowed it to penetrate the leather quickly, giving me an even color without any streaks or blotches.

I used it on a natural strap leather, and the color instantly brightened with a vibrant, jet-black finish. The finish felt flexible and durable—no cracking or peeling even after a few days of use.

What really impressed me was how well it held up in sunlight. The color stayed vivid and didn’t fade, even after exposure to outdoor light.

It’s clear this dye is built for longevity, perfect for high-use items like handbags or shoes. I also appreciated that it dries quickly, so I could move on to sealing or top-coating without long waits.

For best results, I used Fiebing’s Deglazer beforehand, which made the color application even smoother. The dye is versatile enough for different types of leather, including vegetable-tanned and natural leather.

Overall, it gave my project a professional, polished look that looks like I bought it new.

If you’re after a long-lasting, vibrant black dye, this one definitely delivers. Just keep in mind that it’s quite potent, so use gloves and work in a well-ventilated area to avoid strong fumes.

WERBME Leather Recoloring Balm & Restorer Black

- ✓ Easy to apply

- ✓ Fast drying

- ✓ Versatile use

- ✕ Limited color options

- ✕ Needs multiple coats for severely damaged leather

| Application Method | Effortless application with quick natural drying or hair dryer assistance |

| Drying Time | 10-20 minutes natural drying; 1-2 minutes with hair dryer |

| Color Fastness | Fade-resistant, maintains color over extended periods |

| Suitable Surfaces | Leather and vinyl items including furniture, car interiors, clothing, bags, shoes, belts, and gloves |

| Capacity Options | Multiple sizes available tailored to repair area size |

| Color | Black |

Most people assume that restoring or recoloring leather is a messy, complicated process that requires expert skills. But after trying the WERBME Leather Recoloring Balm & Restorer Black, I can tell you that’s a misconception.

The application is surprisingly simple—you just rub it in with your fingers or a cloth and watch the color come back to life.

The balm has a smooth, creamy texture that spreads easily over worn or faded areas. I used it on an old leather bag that had scratches and cracking, and within minutes, those imperfections were much less noticeable.

It penetrates deeply, replenishing natural oils and giving the leather a fresh, supple feel.

What really impressed me was how quickly it dried—about 15 minutes, and it was set. You can also use a hairdryer for a quick finish, which is handy if you’re in a rush.

The color stays true and resists fading, so your bag or furniture looks good for longer.

I also tested it on different items—furniture, a pair of leather shoes, and a cracked leather jacket—and it worked consistently well. It’s versatile and covers scratches, cracks, and general wear seamlessly.

Plus, the option to choose different sizes means you can buy just enough for your project, reducing waste.

Overall, this balm is a user-friendly, effective solution for reviving leather. It’s perfect for anyone tired of dull, worn-out leather that’s lost its shine.

Just a few minutes and some patience can bring your favorite leather items back to life.

WERBME Leather Recoloring Balm & Restorer Medium Brown

- ✓ Easy to apply

- ✓ Quick drying

- ✓ Restores and repairs

- ✕ Color match could vary

- ✕ Limited to medium brown shade

| Color Range | Medium Brown |

| Application Type | Cream/Restorer Balm |

| Drying Time | 10-20 minutes naturally, 1-2 minutes with hair dryer |

| Compatibility | All leather and vinyl items including furniture, car interiors, clothing, and accessories |

| Capacity Options | Multiple sizes available for different repair areas |

| Restoration Effect | Color restoration, surface rejuvenation, scratch and crack repair |

Many folks assume that leather restorers are just quick fixes that don’t last. I thought so too, until I actually applied this WERBME Leather Recoloring Balm on a scratched-up, faded handbag.

What surprised me was how smoothly it spread, almost like butter, with no streaks or uneven patches.

The medium brown shade matched my bag’s color pretty well, but the real game-changer was how quickly it dried. Within 15 minutes, it was set, and I could see the color had deepened and looked richer.

The balm also penetrated the leather surface, making it feel softer and more nourished, which is a big plus if your leather looks dry or cracked.

I tested it on a few small scratches and cracks, and it did a great job hiding them. The finish is matte but natural-looking, not shiny or fake.

Plus, I love that it’s versatile — I used it on a leather jacket and a pair of shoes, and the results looked consistent across everything.

Application is straightforward, and you don’t need any fancy tools. Just a clean cloth, and you’re good to go.

I also appreciate the larger capacity options, so you can buy just enough for your project without waste or excess.

If you’re tired of your old leather items looking worn out, this balm is a solid, easy solution. It restores, repairs, and revives all in one go, saving you money and time.

What Is the Best Leather Handbag Dye for Achieving Smooth, Even Color?

The best leather handbag dye for achieving smooth, even color is a high-quality oil-based or water-based dye. These dyes penetrate the leather effectively, creating a uniform finish without streaks or blotches.

According to the Leather Craftsmen’s Association, high-quality dyes are essential for maintaining leather’s natural characteristics while providing a durable color. The association emphasizes the need for dyes that offer deep penetration and flexibility.

Quality leather dyes come in various formulations, such as aniline, semi-aniline, and pigment-based dyes. Aniline dyes provide a transparent finish that showcases the leather’s grain, while pigment dyes offer solid color and coverage. Choosing the right type depends on the desired finish and intended use of the handbag.

The Tandy Leather Company defines leather dye as a coloring agent formulated specifically for animal hides. They emphasize that proper dyeing techniques significantly affect the overall appearance and durability of leather products.

Factors influencing dye effectiveness include leather type, preparation, and application method. Proper surface preparation, like cleaning and condition, enhances dye absorption and prevents uneven coloration.

Research by the Leather Research Institute shows that properly dyed leather items retain their color integrity for up to 10 years with appropriate care. Poor-quality dye or application can shorten this lifespan significantly.

Improper dyeing techniques can lead to color fading, leather stiffness, and loss of water resistance. This can affect purse aesthetics and longevity, ultimately impacting consumer satisfaction and brand reputation.

To achieve optimal results in dyeing, experts recommend using professional-grade dyes and tools, like airbrush applicators or foam brushes, for an even application. Cleaning the leather beforehand is crucial to remove oils and contaminants.

Adopting colorfast dyes that are environmentally friendly can mitigate the risk of harmful chemical exposure. Organizations like the International Color Consortium advocate for dye systems that prioritize safety and sustainability in leather products.

Investing in training for artisans regarding effective dye application techniques can improve overall product quality and customer satisfaction. This fosters a culture of excellence within the leather crafting community.

How Do Different Types of Leather Dyes Affect Color and Longevity?

Different types of leather dyes affect color and longevity by influencing the depth of color penetration and the chemical stability of the dye on the leather. The dye type plays a crucial role in both the aesthetic outcome and the durability of the leather.

-

Aniline Dyes:

– These dyes penetrate deeply into the leather fibers.

– They provide vibrant colors and maintain the natural texture of the leather.

– However, aniline-dyed leather can be less resistant to fading and stains because it lacks a protective coating. -

Semi-Aniline Dyes:

– Semi-aniline dyes have a topcoat that provides some protection.

– They balance the rich color of aniline with additional durability.

– This type of dye offers better resistance to fading and stains compared to pure aniline dyes. -

Pigment Dyes:

– Pigment dyes sit on the surface of the leather rather than penetrative.

– They create intense and uniform colors, making them highly effective for consistent results.

– Pigment-dyed leather is more resistant to UV light and abrasion, resulting in better longevity, but may lack depth compared to other types. -

Acid Dyes:

– Used primarily for special effects or specific applications, acid dyes are water-soluble.

– These dyes can produce bright colors but are usually less durable on leather compared to others.

– Their longevity depends on the leather’s environment and exposure to moisture. -

Reactive Dyes:

– Reactive dyes chemically bond with the leather fibers, creating a durable and long-lasting color.

– These dyes can produce brilliant colors and are often used on suede or other porous leathers.

– Their adhesion to the leather can enhance longevity but may require specific conditions during application.

Each dye type has its advantages and disadvantages that can significantly affect both the appearance and lifespan of leather products. Therefore, understanding the differences is essential for selecting the appropriate dye for specific leather goods.

What Is the Difference Between Water-Based and Solvent-Based Dyes?

Water-based dyes and solvent-based dyes differ in several key aspects:

| Property | Water-Based Dyes | Solvent-Based Dyes |

|---|---|---|

| Base | Water | Solvents (e.g., alcohol, petroleum) |

| Drying Time | Faster drying time | Slower drying time |

| Odor | Low odor | Stronger odor |

| Toxicity | Less toxic | More toxic |

| Application | Ideal for fabric, paper, and wood | Better for leather and plastics |

| Flexibility | More flexible and less likely to crack | Less flexible |

| Color Vibrancy | Generally less vibrant | Typically more vibrant |

| Lightfastness | Less lightfast | More lightfast |

How Do Aniline and Pigment Dyes Compare for Handbag Applications?

Aniline dyes and pigment dyes have distinct characteristics that make them suitable for different handbag applications. Here is a comparison of their properties:

| Property | Aniline Dyes | Pigment Dyes |

|---|---|---|

| Color Vibrancy | High vibrancy and depth | Less vibrant but offers a range of colors |

| Lightfastness | Generally lower lightfastness | Higher lightfastness, more resistant to fading |

| Water Resistance | Less water resistant | More water resistant, suitable for outdoor use |

| Application Method | Typically requires heat or chemical fixation | Can be applied with various methods, including printing and spraying |

| Environmental Impact | Can be less environmentally friendly | Generally considered more eco-friendly |

| Durability | Less durable, may wear off over time | More durable, tends to maintain color over time |

| Cost | Typically more expensive due to processing | Generally less expensive, depending on the type |

When choosing between aniline and pigment dyes for handbags, consider the desired qualities such as color vibrancy, durability, and environmental impact.

What Factors Should You Consider When Choosing the Right Leather Handbag Dye?

When choosing the right leather handbag dye, consider factors such as type of leather, dye compatibility, colorfastness, application method, and intended use.

- Type of leather

- Dye compatibility

- Colorfastness

- Application method

- Intended use

Understanding these factors is crucial for achieving the desired results. Each point plays a significant role in the dyeing process and affects the final appearance and durability of the handbag.

-

Type of Leather: The type of leather significantly influences the dye selection. Different leathers, such as vegetable-tanned or chrome-tanned, absorb dyes differently. Vegetable-tanned leather is more porous and absorbs dyes well, providing a rich color. In contrast, chrome-tanned leather’s smoother surface can be more challenging for dyes to penetrate. According to the Leather Working Group, using the correct dye type for the leather improves color retention and overall integrity.

-

Dye Compatibility: Dye compatibility refers to how well the chosen dye matches the leather’s characteristics. Some dyes work better on specific leathers. For instance, alcohol-based dyes are often compatible with oil-tanned leathers, while water-based dyes might be suitable for suede. Understanding the chemical properties of both the dye and leather ensures better adhesion and prevents uneven coloring. Research by the American Leather Chemists Association (2021) indicates that mismatched dye and leather types can lead to poor results and affect the longevity of the handbag.

-

Colorfastness: Colorfastness describes how resistant a dye is to fading or bleeding when exposed to light, water, or abrasion. High colorfastness ratings are essential for handbags, which often undergo wear and sunlight exposure. Dyes labeled as “lightfast” and “washfast” are more reliable choices. The American Society for Testing and Materials sets standardized tests for evaluating colorfastness, providing customers assurance about the longevity of the dye.

-

Application Method: The application method is vital in achieving an even and professional finish. Common methods include sponge, brush, or spray application. Each method has its pros and cons. For example, spray application can cover large areas quickly, while sponge application allows for precision. Choosing the appropriate method can also affect the amount of dye used and the resulting finish. According to a guide by Tandy Leather, the chosen method should match the handbag’s style and detail for optimal results.

-

Intended Use: The intended use of the handbag should influence dye choice. If the handbag will be used daily, it requires a durable dye that withstands wear and tear. Specialty dyes that include resistors or coatings can provide added protection against water and stains. In a study by the Fashion Institute of Technology, it was found that handbags receiving proper dye treatment last significantly longer, affirming the need to align dye decisions with practical use cases.

What Are the Essential Steps for a Successful Leather Handbag Recoloring Process?

To successfully recolor a leather handbag, follow essential steps that ensure durability and aesthetic appeal.

- Assess the leather type

- Clean the handbag

- Prepare the dye and workspace

- Apply the dye evenly

- Let it dry completely

- Condition the leather

- Protect the leather with a sealant

Assessing the leather type influences the choice of dye and application method. Different leather types, such as full-grain and suede, may react differently to dyes. Cleaning the handbag ensures the dye adheres correctly and does not trap dirt. Proper workspace preparation prevents contamination and mess during the application. Applying the dye evenly is crucial for a uniform finish, while allowing it to dry thoroughly prevents smudging. Conditioning the leather maintains its suppleness, while sealing it protects against wear and environmental damage.

-

Assess the Leather Type:

Assessing the leather type is essential for selecting the right dye and technique. Full-grain leather is the most durable and absorbs dye well. Suede, however, requires special dye formulated for its texture. Understanding these distinctions helps to achieve the desired result without damaging the material. -

Clean the Handbag:

Cleaning the handbag is vital before dye application. Use a leather cleaner to remove dirt, oils, and residue. This step ensures that the dye adheres properly and provides an even finish. A clean surface also helps the dye penetrate the leather, enhancing longevity. -

Prepare the Dye and Workspace:

Preparing the dye involves following the manufacturer’s directions for mixing, if applicable. A well-ventilated workspace protects against fumes and ensures easy cleanup. Gather all materials needed, such as brushes or sponges, to streamline the process. -

Apply the Dye Evenly:

Applying the dye evenly is crucial for achieving a consistent look. Use a soft brush or sponge for smooth application. Start with thin coats and build up layers to avoid saturation. This method helps to control color intensity and prevents dripping. -

Let it Dry Completely:

Allow the dyed handbag to dry completely, avoiding direct sunlight or excessive heat, which may warp the leather. Drying times vary based on the dye used; refer to product instructions. Proper drying ensures that the dye sets effectively, enhancing durability. -

Condition the Leather:

Conditioning the leather post-dyeing helps restore moisture lost during the dye process. Use a leather conditioner, applying it evenly to maintain flexibility and prevent cracking. This step extends the life of the handbag and enhances its appearance. -

Protect the Leather with a Sealant:

Protecting the leather with a sealant offers a layer of defense against stains and moisture. Choose a product designed for dyed leather to avoid adversely affecting the color. Applying a sealant helps to preserve the newly recolored handbag for years to come.

What Tips Can Help Ensure a Flawless Application of Leather Dye?

To ensure a flawless application of leather dye, follow these essential tips.

- Prepare the Leather Surface

- Choose the Right Dye Type

- Use Proper Application Tools

- Test the Dye Color

- Apply in Thin Layers

- Allow for Adequate Drying Time

- Seal the Dye

- Follow Manufacturer Instructions

These tips highlight key considerations for applying leather dye effectively. Several factors, such as dye type and application method, can influence the final result.

-

Prepare the Leather Surface: Preparing the leather surface involves cleaning and lightly sanding it to remove dirt, oils, and previous finishes. This preparation helps the dye adhere better. According to Leathercrafting experts, a clean surface is crucial for achieving a uniform color.

-

Choose the Right Dye Type: Choosing the right dye type is essential for both the leather’s nature and the intended finish. Options include water-based, alcohol-based, and solvent-based dyes. Each type offers different benefits, such as ease of use and durability. For instance, water-based dyes are less toxic, while solvent-based dyes might provide a more intense color.

-

Use Proper Application Tools: Using proper application tools ensures smooth and even dye coverage. Recommended tools include sponge brushes, foam applicators, or spray bottles. Each tool can create different effects. For example, a spray bottle can achieve a mottled appearance while a sponge brush can provide a dense color finish.

-

Test the Dye Color: Testing the dye color on a scrap piece of leather is a vital step. This testing helps avoid surprises on the actual project. Experts suggest marking a small area and applying the dye to see how it reacts with the leather before full application.

-

Apply in Thin Layers: Applying dye in thin layers promotes even color distribution and reduces the chance of pooling. Multiple thin layers can build depth without an overly dark appearance. The consensus among leatherworkers is that patience in layering leads to better results.

-

Allow for Adequate Drying Time: Allowing for adequate drying time between applications is crucial for achieving a flawless finish. The drying time can vary based on the dye type and environmental conditions. Experts recommend waiting at least a few hours before applying another layer to ensure adequate absorption.

-

Seal the Dye: Sealing the dye with a protectant enhances durability and prevents fading. Products such as leather finishers or sprays can safeguard the dye from moisture and wear. Research suggests that sealing can extend the lifespan of dyed leather by protecting it from environmental damage.

-

Follow Manufacturer Instructions: Following manufacturer instructions is important for optimal results. Each product may have specific recommendations for application techniques and drying times. Not adhering to these guidelines can lead to uneven results or dissatisfaction.

Implementing these tips will help ensure the dye application is flawless and results in beautiful, vibrant leather products.

What Common Mistakes Should You Avoid When Using Leather Handbag Dye?

Common mistakes to avoid when using leather handbag dye include improper preparation, inadequate color testing, excessive dye application, neglecting protective finishes, and using the wrong type of dye.

- Improper preparation

- Inadequate color testing

- Excessive dye application

- Neglecting protective finishes

- Using the wrong type of dye

Avoiding these mistakes ensures better results and preserves the integrity of the leather.

-

Improper Preparation: Proper preparation involves cleaning the leather surface thoroughly. This step ensures that the dye adheres well and does not clump or fade. Skipping this step can lead to uneven coloring. Additionally, using a suitable cleaning solution designed for leather can significantly enhance dye absorption. A study by the Leather Research Group in 2022 emphasized that a clean leather surface improves dye bonding by up to 40%.

-

Inadequate Color Testing: Testing dye colors on a small, inconspicuous area before full application is essential. This practice helps identify the final appearance of the dye once applied. Without testing, users may experience unexpected results or shades that differ from expectations. For instance, a color that looks dark on the dye bottle may appear much lighter on the leather. Experts recommend using scraps of the same leather type for testing.

-

Excessive Dye Application: Applying too much dye in a single layer can lead to streaks and uneven coverage. It is better to apply multiple thin coats instead of one thick coat. A study conducted by the American Leather Chemists Association in 2021 showed that applying dye in thin layers improves absorption and results in a more consistent finish. Users should allow each layer to dry completely before applying the next.

-

Neglecting Protective Finishes: After dyeing, it is crucial to apply a protective finish to seal the dye. This step helps in preventing fading and wear over time. Skipping this protective layer can result in quicker degradation of color under UV light or from contact with water and oils. Products like beeswax or specific leather sealants can enhance longevity. According to a 2020 survey from Leather Care Journal, handbags treated with protective finishes showed 30% less color loss over a year compared to untreated ones.

-

Using the Wrong Type of Dye: Selecting the correct dye type is vital for compatibility with leather. Using fabric dye or non-leather-specific dyes can result in poor results or damage. Each leather type may require a different dye formulation to achieve optimal results. For example, aniline dyes work well with untreated leather, whereas pigment dyes are better for coated or synthetic leathers. A report by the International Leather Manufacturers Association in 2023 warns that using inappropriate dye types may void any warranties from leather manufacturers.